At present there are 2 main types of robots, based on their use:

general-purpose autonomous robots and dedicated robots.

Robots can be classified by their

specificity of purpose. A robot might be designed to perform one particular task extremely well, or a range of tasks less well. Of course, all robots by their nature can be re-programmed to behave differently, but some are limited by their physical form. For example, a factory robot arm can perform jobs such as cutting, welding, gluing, or acting as a fairground ride, while a pick-and-place robot can only populate printed circuit boards.

General-purpose autonomous robots

General-purpose autonomous robots can perform a variety of functions independently. General-purpose autonomous robots typically can navigate independently in known spaces, handle their own re-charging needs, interface with electronic doors and elevators and perform other basic tasks. Like computers, general-purpose robots can link with networks, software and accessories that increase their usefulness. They may recognize people or objects, talk, provide companionship, monitor environmental quality, respond to alarms, pick up supplies and perform other useful tasks. General-purpose robots may perform a variety of functions simultaneously or they may take on different roles at different times of day. Some such robots try to mimic human beings and may even resemble people in appearance; this type of robot is called a humanoid robot.

A general-purpose robot acts as a guide during the day and a security guard at night

Factory robots

- Car production

Over the last three decades automobile factories have become dominated by robots. A typical factory contains hundreds of

industrial robots working on fully automated production lines, with one robot for every ten human workers. On an automated production line, a vehicle chassis on a conveyor is

welded,

glued, painted and finally assembled at a sequence of robot stations.

An intelligent AGV drops-off goods without needing lines or beacons in the workspace

- Packaging

Industrial robots are also used extensively for palletizing and packaging of manufactured goods, for example for rapidly taking drink cartons from the end of a conveyor belt and placing them into boxes, or for loading and unloading machining centers.

- Electronics

Mass-produced

printed circuit boards (PCBs) are almost exclusively manufactured by pick-and-place robots, typically with

SCARA manipulators, which remove tiny

electronic components from strips or trays, and place them on to PCBs with great accuracy.

Such robots can place hundreds of thousands of components per hour, far out-performing a human in speed, accuracy, and reliability.

- Automated guided vehicles (AGVs)

Mobile robots, following markers or wires in the floor, or using vision

or lasers, are used to transport goods around large facilities, such as warehouses, container ports, or hospitals.

-

- Early AGV-Style Robots

- Limited to tasks that could be accurately defined and had to be performed the same way every time. Very little feedback or intelligence was required, and the robots needed only the most basic exteroceptors (sensors). The limitations of these AGVs are that their paths are not easily altered and they cannot alter their paths if obstacles block them. If one AGV breaks down, it may stop the entire operation.

-

- Interim AGV-Technologies

- Developed to deploy triangulation from beacons or bar code grids for scanning on the floor or ceiling. In most factories, triangulation systems tend to require moderate to high maintenance, such as daily cleaning of all beacons or bar codes. Also, if a tall pallet or large vehicle blocks beacons or a bar code is marred, AGVs may become lost. Often such AGVs are designed to be used in human-free environments.

-

- Intelligent AGVs (i-AGVs)

- Such as SpeciMinder, ADAM, Tug and MT 400 with Motivity are designed for people-friendly workspaces. They navigate by recognizing natural features. 3D scanners or other means of sensing the environment in two or three dimensions help to eliminate cumulative errors in dead-reckoning calculations of the AGV's current position. Some AGVs can create maps of their environment using scanning lasers with simultaneous localization and mapping (SLAM) and use those maps to navigate in real time with other path planning and obstacle avoidance algorithms. They are able to operate in complex environments and perform non-repetitive and non-sequential tasks such as transporting photomasks in a semiconductor lab, specimens in hospitals and goods in warehouses. For dynamic areas, such as warehouses full of pallets, AGVs require additional strategies using three-dimensional sensors such as time-of-flight or stereovision cameras.

Dirty, dangerous, dull or inaccessible tasks

There are many jobs which humans would rather leave to robots. The job may be boring, such as domestic

cleaning, or dangerous, such as exploring inside a

volcano.

Other jobs are physically inaccessible, such as exploring another

planet,

cleaning the inside of a long pipe, or performing

laparoscopic surgery.

- Space probes

Almost every unmanned

space probe ever launched was a robot. Some were launched in the 1960s with more limited abilities, but their ability to fly and to land (in the case of

Luna 9) is an indication of their status as a robot. This includes the

Voyager probes and the Galileo probes, as well as other probes.

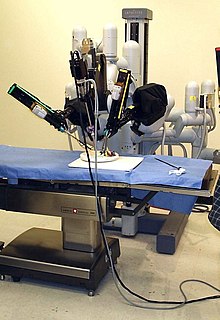

- Telerobots

When a human cannot be present on site to perform a job because it is dangerous, far away, or inaccessible, teleoperated robots, or telerobots are used. Rather than following a predetermined sequence of movements, a telerobot is controlled from a distance by a human operator. The robot may be in another room or another country, or may be on a very different scale to the operator. For instance, a laparoscopic surgery robot allows the surgeon to work inside a human patient on a relatively small scale compared to open surgery, significantly shortening recovery time.

When disabling a bomb, the operator sends a small robot to disable it. Several authors have been using a device called the Longpen to sign books remotely.

Teleoperated robot aircraft, like the Predator

Unmanned Aerial Vehicle, are increasingly being used by the military. These pilotless drones can search terrain and fire on targets.

Hundreds of robots such as

iRobot's Packbot and the

Foster-Miller TALON are being used in

Iraq and

Afghanistan by the

U.S. military to defuse roadside bombs or

Improvised Explosive Devices (IEDs) in an activity known as

explosive ordnance disposal (EOD).

- Automated fruit harvesting machines

Used to pick fruit on orchards at a cost lower than that of human pickers.

- In the home

As prices fall and robots become smarter and more autonomous, simple robots dedicated to a single task work in over a million homes. They are taking on simple but unwanted jobs, such as

vacuum cleaning and

floor washing, and

lawn mowing. Some find these robots to be cute and entertaining, which is one reason that they can sell very well.

- Duct Cleaning

The ANATROLLER ARI-100 is a modular mobile robot used for cleaning hazardous environments

In the hazardous and tight spaces of a building's duct work, many hours can be spent cleaning relatively small areas if a manual brush is used. Robots have been used by many duct cleaners primarily in the industrial and institutional cleaning markets, as they allow the job to be done faster, without exposing workers to the harmful enzymes released by dust mites. For cleaning high-security institutions such as embassies and prisons, duct cleaning robots are vital, as they allow the job to be completed without compromising the security of the institution. Hospitals and other government buildings with hazardous and cancerogenic environments such as nuclear reactors legally must be cleaned using duct cleaning robots, in countries such as Canada, in an effort to improve workplace safety in duct cleaning.

Military robots

Military robots include the

SWORDS robot which is currently used in ground-based combat. It can use a variety of weapons and there is some discussion of giving it some degree of autonomy in battleground situations.

Unmanned combat air vehicles (UCAVs), which are an upgraded form of

UAVs, can do a wide variety of missions, including combat. UCAVs are being designed such as the

Mantis UCAV which would have the ability to fly themselves, to pick their own course and target, and to make most decisions on their own.

The

BAE Taranis is a UCAV built by Great Britain which can fly across continents without a pilot and has new means to avoid detection.

Flight trials are expected to begin in 2011.

The AAAI has studied this topic in depth

and its president has commissioned a study to look at this issue.

Some have suggested a need to build "

Friendly AI", meaning that the advances which are already occurring with AI should also include an effort to make AI intrinsically friendly and humane.

Several such measures reportedly already exist, with robot-heavy countries such as Japan and South Korea

having begun to pass regulations requiring robots to be equipped with safety systems, and possibly sets of 'laws' akin to Asimov's

Three Laws of Robotics.

An official report was issued in 2009 by the Japanese government's Robot Industry Policy Committee.

Chinese officials and researchers have issued a report suggesting a set of ethical rules, as well as a set of new legal guidelines referred to as "Robot Legal Studies."

Some concern has been expressed over a possible occurrence of robots telling apparent falsehoods.

Schools

Robotics have also been introduced into the lives of elementary and high school students with the company

FIRST (For Inspiration and Recognition of Science and Technology). The organization is the foundation for the

FIRST Robotics Competition,

FIRST LEGO League,

Junior FIRST LEGO League, and

FIRST Tech Challenge competitions.

Healthcare

Robots in healthcare have two main functions. Those which assist an individual, such as a sufferer of a disease like Multiple Sclerosis, and those which aid in the overall systems such as pharmacies and hospitals.

- Home automation for the elderly and disabled

Robots have developed over time from simple basic robotic assistants, such as the

Handy 1,

through to semi-autonomous robots, such as

FRIEND which can assist the elderly and disabled with common tasks.

The population is

aging in many countries, especially Japan, meaning that there are increasing numbers of elderly people to care for, but relatively fewer young people to care for them.

Humans make the best carers, but where they are unavailable, robots are gradually being introduced.

FRIEND is a semi-autonomous robot designed to support

disabled and

elderly people in their daily life activities, like preparing and serving a meal. FRIEND make it possible for

patients who are

paraplegic, have muscle diseases or serious

paralysis (due to strokes etc.), to perform tasks without help from other people like therapists or nursing staff.

- Pharmacies

Script Pro manufactures a robot designed to help pharmacies fill prescriptions that consist of oral solids or

medications in pill form. The

pharmacist or

pharmacy technician enters the prescription information into its information system. The system, upon determining whether or not the drug is in the robot, will send the information to the robot for filling. The robot has 3 different size vials to fill determined by the size of the pill. The robot technician, user, or pharmacist determines the needed size of the vial based on the tablet when the robot is stocked. Once the vial is filled it is brought up to a conveyor belt that delivers it to a holder that spins the vial and attaches the patient label. Afterwards it is set on another conveyor that delivers the patient’s medication vial to a slot labeled with the patient's name on an LED read out. The pharmacist or technician then checks the contents of the vial to ensure it’s the correct drug for the correct patient and then seals the vials and sends it out front to be picked up. The robot is a very time efficient device that the pharmacy depends on to fill prescriptions.

McKesson’s Robot RX is another healthcare robotics product that helps pharmacies dispense thousands of medications daily with little or no errors. The robot can be ten feet wide and thirty feet long and can hold hundreds of different kinds of medications and thousands of doses. The pharmacy saves many resources like staff members that are otherwise unavailable in a resource scarce industry. It uses an

electromechanical head coupled with a

pneumatic system to capture each dose and deliver it to its either stocked or dispensed location. The head moves along a single axis while it rotates 180 degrees to pull the medications. During this process it uses

barcode technology to verify its pulling the correct drug. It then delivers the drug to a patient specific bin on a conveyor belt. Once the bin is filled with all of the drugs that a particular patient needs and that the robot stocks, the bin is then released and returned out on the conveyor belt to a technician waiting to load it into a cart for delivery to the floor.

Research robots

While most robots today are installed in factories or homes, performing labour or life saving jobs, many new types of robot are being developed in

laboratories around the world. Much of the research in robotics focuses not on specific industrial tasks, but on investigations into new types of robot, alternative ways to think about or design robots, and new ways to manufacture them. It is expected that these new types of robot will be able to solve real world problems when they are finally realized.

- Nanorobots

A microfabricated electrostatic gripper holding some silicon nanowires.

Nanorobotics is the still largely hypothetical technology of creating machines or robots at or close to the scale of a

nanometer (10

−9 meters). Also known as "nanobots" or "nanites", they would be constructed from

molecular machines. So far, researchers have mostly produced only parts of these complex systems, such as bearings, sensors, and

Synthetic molecular motors, but functioning robots have also been made such as the entrants to the Nanobot Robocup contest.

Researchers also hope to be able to create entire robots as small as viruses or bacteria, which could perform tasks on a tiny scale. Possible applications include micro surgery (on the level of individual

cells),

utility fog,

manufacturing, weaponry and cleaning.

Some people have suggested that if there were nanobots which could reproduce, the earth would turn into "

grey goo", while others argue that this hypothetical outcome is nonsense.

- Reconfigurable Robots

A few researchers have investigated the possibility of creating robots which can

alter their physical form to suit a particular task,

like the fictional

T-1000. Real robots are nowhere near that sophisticated however, and mostly consist of a small number of cube shaped units, which can move relative to their neighbours, for example

SuperBot. Algorithms have been designed in case any such robots become a reality.

- Soft Robots

Robots with

silicone bodies and flexible actuators (

air muscles,

electroactive polymers, and

ferrofluids), controlled using

fuzzy logic and

neural networks, look and feel different from robots with rigid skeletons, and are capable of different behaviors.

- Swarm robots

A

swarm of robots from the Open-source Micro-robotic Project

Inspired by

colonies of insects such as

ants and

bees, researchers are modeling the behavior of

swarms of thousands of tiny robots which together perform a useful task, such as finding something hidden, cleaning, or spying. Each robot is quite simple, but the

emergent behavior of the swarm is more complex. The whole set of robots can be considered as one single distributed system, in the same way an ant colony can be considered a

superorganism, exhibiting

swarm intelligence. The largest swarms so far created include the iRobot swarm, the SRI/MobileRobots CentiBots project

and the Open-source Micro-robotic Project swarm, which are being used to research collective behaviors.

Swarms are also more resistant to failure. Whereas one large robot may fail and ruin a mission, a swarm can continue even if several robots fail. This could make them attractive for space exploration missions, where failure is normally extremely costly.

- Haptic interface robots

Robotics also has application in the design of

virtual reality interfaces. Specialized robots are in widespread use in the

haptic research community. These robots, called "haptic interfaces," allow touch-enabled user interaction with real and virtual environments. Robotic forces allow simulating the mechanical properties of "virtual" objects, which users can experience through their sense of

touch.